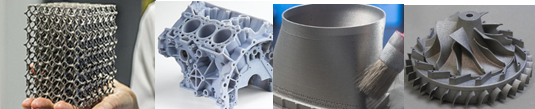

Additive Manufacturing is a process to produce complex form of structures with the help of 3D-datas either as a prototyp or in mass production. A subarea is the powder metallurgy, which can be devided into selective laser melting and sintering. The basic priciple is to deposite a thin film of either metallic or plastic powder on a baseplate. A focussed laser beam, according to the 3D-datas and deflected by the beam deflection unit, leads the powder to melt and finally to solidify. Afterwards the motorized baseplate sinks the amount of the deposit thickness and be re-coated with powder. This cycle will be continued until the element is being finished. Because of the high degree of digitalization of each single section, this process supports the idea of “industry 4.0”.

Optoprim France

Optoprim France Optoprim Italy

Optoprim Italy